Timing:

Turbo replacement

is the primary reason to pull the engine. Might be because of a spun bearing,

a thrown rod or some other required internals repair. Even better is a

full engine build up for monster hp.

Special

tools:

1 ton engine

hoist or stonger

Chains to

go with hoist

Load leveler

with hoist is an extra

36" 1/2" drive

socket extension for the transmission

Fender service

cover (4.) is one of the BEST tools I own.

1. Relieve

Fuel Pressure:

Remove relay, start the car until fuel is spent (Details

step 1-4)

2. Drain

Fluids & Remove Battery

Drain oil & remove filter (Details

step 2-6)

Drain coolant (Details

step 2)

Unplug negative terminal, make sure it can't come back in contact with

the post

Remove battery (remove the cowling 4 plastic clips & battery strap

2 x 10mm)

Set battery on a wood block so it doesn't discharge

Prop hood at highest setting (there's more than one)

3. Remove

Radiator, Fan & Drive Belts

Remove radiator, fan & drive belts (Details

step 3-8)

4. Remove

Alternator from the engine

Loosen mounting bracket on engine block (1 x 12mm)

Remove upper pivot bolt (1 x 17mm)

Note: The nut on the backside will fall out, it's got a special tab welded on it & isn't secure to anything.

Lower alternator

5. Remove

AC compressor from engine

Remove lower mounting bolts (2 x 14mm)

Remove upper mounting bolts (2 x 14mm)

Note: The top back bolt is impossible to get to from the rear. I used a 14mm crows foot on a 9" extension to get to it from the front. Go over the top of the AC compressor to get to the bolt backwards. Remember tight & loose are reversed from this angle! I'm not sure how easy it is to do this with the engine bolted in the car. I was able to get to it 'easily' once the engine was slightly lifted & tilting backwards. This bolt is absolutely not required on re-assembly. Nissan dealers do not replace it from what I've seen.Disconnect the compressor clutch plug

Wire Compressor to side of engine bay, forward & to the right, being careful not to twist the hoses

6. Remove

power steering pump from engine

Unbolt pump (1 x 14mm though the holes on the pulley)

Remove the front of the adjustment bracket (2 x 12mm)

Wire pump to left side of engine bay

7. Remove

balance tube & intake hoses

Remove balance tube (Details

step 1-4)

Remove front intake hoses (8 hoseclamps), or 16 if they are coupled hardpipes.

Put rags in all intake tract openings to keep debris out of the

hard pipes

Loosen the clamps on the lower low pressure intake plastic pipes

8. Remove

wiring, etc. on top of engine

Disconnect 6 injectors plugs

Disconnect 6 spark coil plugs

Disconnect fuel temp sensor by #1 cylinder injector

Disconnect all plugs along the driver side:

TPS (2)

boost cut if still running stock boost

Disconnect all plugs along the back side:

idle air control (3, 1 yellow, 2 blue generally)

O2

EGR temp (all Cali cars and '96ers)

grounding groups (2)

VTC

detonation sensor

Disconnect all plugs along the passenger side:Note: The VTC and detonation sensor have identical plugs, it's easy to get them confused when reconnecting things later. To identify them now: The det. sensor plug should be vertical dead center in the rear of the engine, the VTC connector should be on the driver side paired with the O2 sensor. To identify them later: The VTC wire on the engine side has a white shielding jacket on it, the det. sensor doesn't. The VTC wire on the harness side will be paired with the driver side O2 sensor, the 4 & 6 coil plugs, a group of grounds and 2 of the idle air control plugs. The det. sensor will be paired with all of the injector plugs, the fuel temp plug, 1,2,3 coil plugs, and the last idle air control plug.

O2

VTC

boost cut if still running stock boost

Remove the oil dipstick

Disconnect hoses along the driver side:

carbon canister hose from under the throttle body

recirc/BOV hose from front vacuum tree

clutch vacuum hose from front vacuum tree

brake vacuum hose from rear vacuum tree

PVRC hose from rear vacuum tree

PVRC hose from fuel lines on the plenum

both fuel hoses

remove the idle air hardpipe

Disconnect hoses along the back side:

water heater hoses (2 x 8mm hoseclamps)

carbon canister from balance tube should already be disconnected

Disconnect hoses along the passenger side:

EGR from rear of engine

EGR from throttlebody

EGR from plastic turbo inlet hose

AIV if equipped

Remove the upper turbo outlet hardpipes (2 x 8mm hoseclamps, 2 x 10mm bolts), stuff rags in openings

9. Attach

engine slingers

Use longer bolts to fit in the rear hole of the side plenum brackets (2

x 12mm)

Attach chains to sides of engine (1. & 2.)

Remove motor mount nuts (2 x 14mm)

Lift up engine weight

10. Remove

Oil Cooler Lines

Unbolt both clamps from oil filter side of oil pan (2 x 8 mm clamps)

11. Disconnect

Steering (not required, but can make things easier)

Unbolt the steering u-joints, remove both bolts (2 x12 mm)

Slide joints upward to come off steering rack

Make sure not to move plastic indexing piece on lower splines

12. Remove

Exhaust

Remove cross brace (4 x 12mm)

Disconnect AIV hoses from the exhausts if it's a '90-'92. (2 x 8 mm hose

clamps)

Unbolt presilencer/H or X pipe from mufflers (hardware depends on exhaust,

4 x 17 mm nuts/bolts for stock)

Unbolt pipes from pre-cats (6 x 13/14 mm depending upon year)

Remove nuts on hanger brackets at the end of transmission (2 x 12 mm nuts)

Remove entire center exhaust assembly

Remove heat shielding (2 x 10mm bolt 4 x 10mm nuts)

13. Remove

Driveshaft

Put transmission in neutral, leave parking brake on

Drop driveshaft support bearing mount (2 x 19mm, don't loose the spacers

on them)

Remove bottom bolts in the middle of driveshaft (2 x 17mm)

Release parking brake, rotate driveshaft 180, set parking brake again

Remove bottom bolts in the middle of driveshaft (other 2 x 17mm)

Separate the driveshaft halves

Remove front half from the transmsission

14. Remove

the Starter

Remove the clutch slave cylinder (2 x 14mm)

Disconnect starter (1 plug, 1 x 12mm nut)

Remove small heat shield window (2 x 10mm)

Remove starter (1 x 14mm bolt, 1 x 14mm nut)

15. Remove

the Transmission

Disconnect 3 plugs on passenger side of transmission

Disconnect shifter bracket (4 x 12mm)

Disconnect shifter (1 x 12mm bolt, 1 x 12mm nut)

Set up the transmission jack, or whatever bracing deemed necessary

Remove bolts on rear transmission mount (6 x 14mm)

Remove bolts on transmission bellhousing (10 x 14mm)

Note: A 36" long 1/2" drive socket extension with a swivel on the end and a 14mm 6 point shallow well socket all on an impact wrench will make this MUCH easier. Just shoot at the bolts from the back of the transmission.Disengage transmission mainshaft from the engine and lower to the ground

16. Hoist

Engine

Use engine hoist to pull out the engine

Disconnect wastegate actuator hoses

17. Re-installing engine is basically a reverse of above steps 16-1.

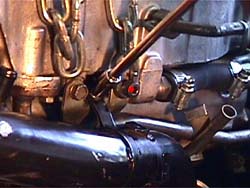

Notes: Install new water heater lines on the firewall. Notice the clamp orientation, this is very important so they can be easily tightened when the engine is back in place (3.).Revised: 6-22-2003When dropping the engine back in be extremely carefull not to snag any wiring around the sides, the AC lines on the passenger side, or crush the power steering lines on the steering rack (4.).

I already put the lower low pressure intake plastic pipes back on the chassis beforehand. Just leave the clamps snug on the front. While the engine is being lowered into the chassis, guide the intake inlets on the turbos into these hoses (5.).

There are also some alternate methods for engine removal. The engine and transmission can be removed together. This entails all the above steps, except Step 15 and the addition of using the Nissan engine slingers and locations. The plenum method of slinging the engine above WILL NOT hold all the weight of the engine plus the transmission, and on top of that, everything would be FAR out of balance. The other problem is the front steering crossmember must be lowered to get the oil pan clear to exit:

Unbolt rear of each front tension rod (4 x 17mm)

Get all power steering lines loosened from rack

Drop front suspension crossmember (4 x 19mm)

It droops down another 6 inches to gain clearance.While this makes it sound easier, it's really not as I discovered when I pulled my first engine. Dropping the front suspension crossmember will almost certainly ruin the car's alignment. Keep in mind you'll have to support 3 things at once now. The chassis on jackstands, the engine on the hoist, and the suspension crossmember on a jack. There's very little room under the car now with all this hardware in the way. Given all the options, dropping the transmission becomes the easiest to do. You can leave the front wheels on ramps to give a lot of elbow room, the rear of the car on jackstands. I've also seen professional mechanics skip all the front fo the engine parts (PS pump, AC compressor, etc) and just break open the lines, removing all accessories with the engine. This is a big time saver, but most of us don't have the tools to recharge the AC lines, etc. For the DIYer, take the extra time to do it.

© Twin Turbo Zs of Dallas - All Rights Reserved 2000

2.

3.

4.

5.